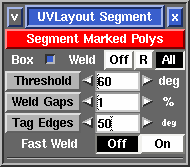

User Guide: Segment

From UVLayout Docs

(Difference between revisions)

| Revision as of 08:55, 28 October 2009 (edit) Headus (Talk | contribs) ← Previous diff |

Revision as of 08:57, 28 October 2009 (edit) (undo) Headus (Talk | contribs) Next diff → |

||

| Line 9: | Line 9: | ||

| ; Threshold : This angle determines at which point adjoining polys are split apart. Increasing this angle will result in less fragmentation (i.e. fewer shells), but there will be more distortion in the resulting UVs and extra cuts or darts may need to be added. Reducing this angle will increase the fragmentation, and so more time will need to be spent welding shells back together. | ; Threshold : This angle determines at which point adjoining polys are split apart. Increasing this angle will result in less fragmentation (i.e. fewer shells), but there will be more distortion in the resulting UVs and extra cuts or darts may need to be added. Reducing this angle will increase the fragmentation, and so more time will need to be spent welding shells back together. | ||

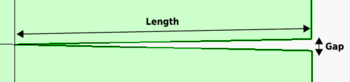

| - | ; Weld Gaps : [[Image:UserGuide-Weld-Gaps.png|right|350px]] During the final welding phase, UVLayout checks for any narrow V shaped seams in the UVs, and these are also stitched up. Normally "narrow" means than the gap between the end points is less than '''1%''' of the length of that edge, but you can increase that with this setting. Increasing the percentage will mean than gaps that are wider will also be stitched up. | + | ; Weld Gaps : [[Image:UserGuide-Weld-Gaps.png|right|350px]] During the final welding phase, UVLayout checks for any narrow V shaped seams in the UVs, and these are also stitched up. Normally "narrow" means than the gap between the end points is less than '''1%''' of the length of that edge, but you can increase that with this setting. A larger percentage will mean that wider gaps will also be stitched up. |

| : If you are unsure, leave it on 1% for the normal segment processing, then check the final results for any V shaped gaps. If you find some, LMB select those shells, increase the percentage, then click the gray '''Weld Gaps''' button to stitch them up. | : If you are unsure, leave it on 1% for the normal segment processing, then check the final results for any V shaped gaps. If you find some, LMB select those shells, increase the percentage, then click the gray '''Weld Gaps''' button to stitch them up. | ||

Revision as of 08:57, 28 October 2009

|

The Segment tool is used to speed up the flattening of "hard" surface geometry, that is, non-organic shapes like buildings, furniture and other props. [Professional Version Only]

|